Bits & Pieces

3D printing is great for prototyping and sometimes final bits

Details

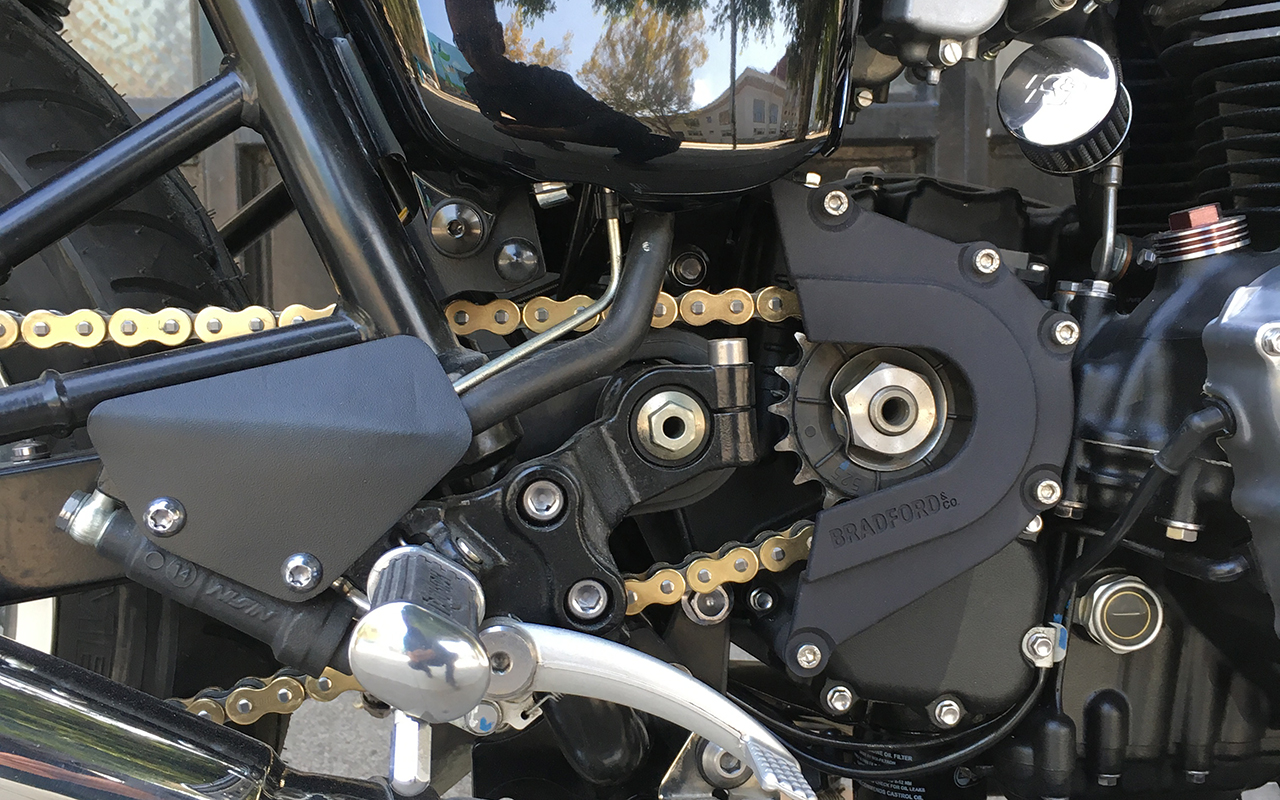

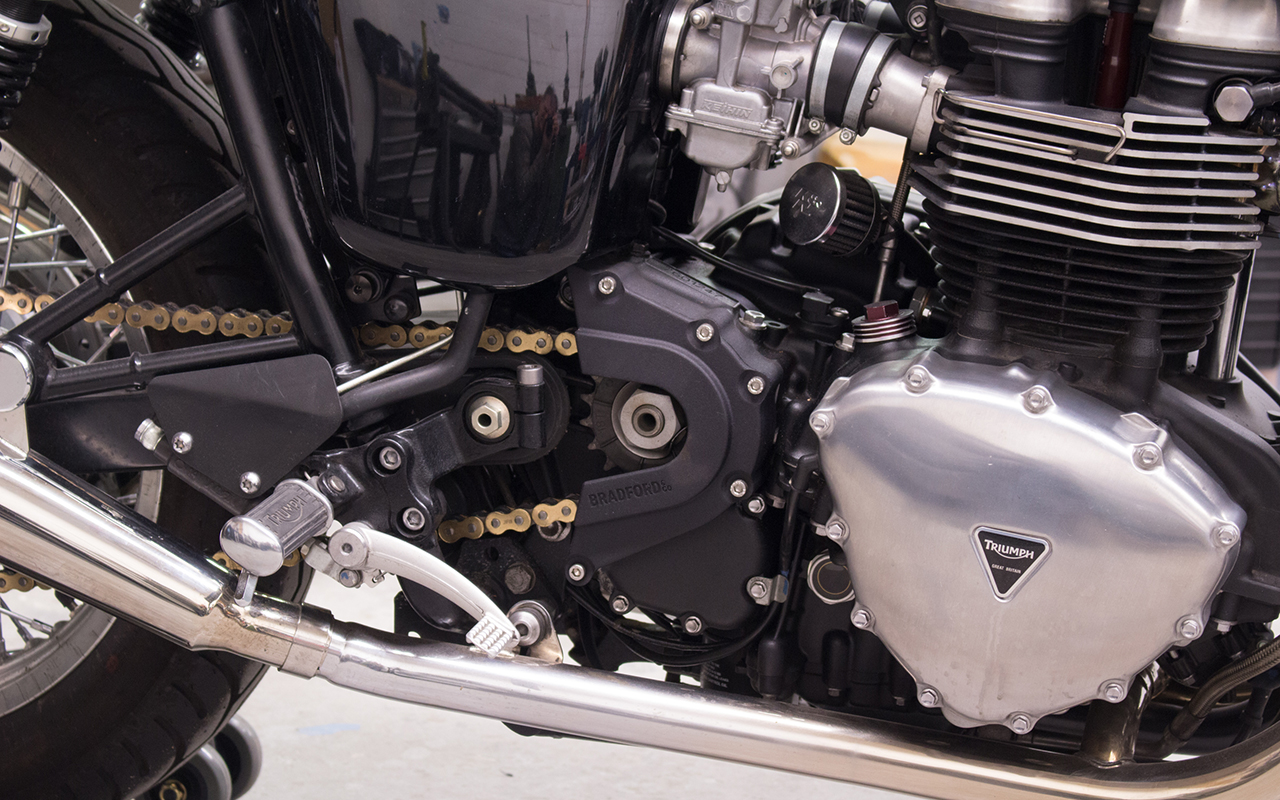

Cleaning up the side profile was a doddle, removing the fake 'gear box' cover and replacing it with a simply designed sprocket cover and ditching the aero inspired heal guard.

The Sprocket Cover is 3D printed in 2 pieces. Surprisingly the texture of the 3D print matches the cast black motor finish, and so far it's held up quite well - we'll be doing a run of these in 6 series aluminium on M-O the CNC as soon as it's up and running if anyone is interested.

The replacement heal guard is simply a piece of Kydex thermal plastic that I cut and shaped.

We've also used 3D printing for our micro-switch housing